STATIC AND DYNAMIC INDUSTRIAL

WEIGHING SYSTEMS

Kit GA1404

Versatile dynamic weighing and dosing system for various types of packaging machines.

It integrates with the packaging process of numerous varieties of products and for different industrial packaging sectors, mainly the food sector.

It consists of a CPU control unit, an HMI DISPLAY panel for viewing and managing data, and one or more I/O boards for integration with the packaging machine.

The system is able to manage the operation of vibrators and belts for transporting the product, monitor the current weight based on the recipe parameters set, manage the informations and communicate with the subsequent components of the packaging line to allow packaging.

➀ CPU control unit

The CPU is the heart of the system and allows you to connect up to four load cells to manage as many weighing units.

The tare and calibration functions allow the use of various types of load cells with different capacities, to meet all speed, accuracy and precision requirements. Each weighing unit can be managed independently or in combination based on the type of product to be packaged but also based on the package itself.

It is possible to set up to 99 recipes, each of which contains all the parameters and times necessary for the operating cycle.

The main interfaces are Ethernet, for communication via Modbus TCP with the display panel, and USB, for updating the system firmware; are also optionally available an RS485 serial, an RS232 serial, a CAN interface, and an expansion module to communicate with other types of protocols, such as PROFINET, EtherCAT and EtherNetIP.

The control and management firmware is equipped with numerous functions and parameters to best adapt to the various components of the line; should additional functionalities become necessary, it is possible to customize them in order to satisfy every need.

Technical characteristics

| Power supply: | 24V / 230VAC |

| Weighing unit: | 1 to 4 |

| Load cell inputs: | 1 to 4 |

| Isolated digital inputs: | 8 to 32 |

| Isolated digital outputs: | 10 to 40 |

| Isolated PWM outputs for vibrators: | 6 to 24 |

| Fast isolated PWM outputs: | 2 to 8 |

| Ethernet interface: | 1 |

| USB interface: | 1 |

| RS485 interface: | 1 |

| RS232 interface: | 1 |

| CAN interface: | 1 |

| Multi-protocol expansion module: | 1 |

| Item weight: | 850 gr. |

| Item size: | 155 x 170 x 140 mm |

Certifications

|  |  |

➁ Power boards

2.1 > Power I/O board AP0727 for vibration channels weighing systems

The I/O board carries out the commands relating to each single weighing unit and allows you to make the necessary wiring to adapt to the packaging machine. It manages up to 6 vibrators in 48V, up to 5 inputs (unloading consent, photocells, auxiliaries) and up to 8 static outputs (brushes, opening command, belts command, auxiliaries).

Technical characteristics

| Static outputs power supply: | 24V |

| Vibrators power supply: | 48V |

| Vibrator outputs: | 6 |

| Inputs: | 5 |

| Static outputs: | 8 |

| Item weight: | 600 gr. |

| Item size: | 210 x 150 x 45 mm |

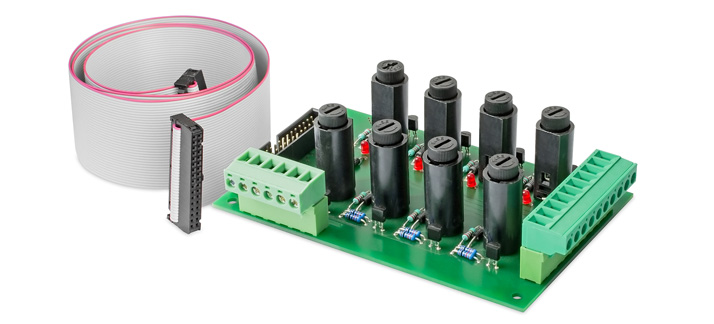

2.2 > I/O BOARD with static outputs 2010 for conveyor belt weighing systems

The I/O board with static outputs (2010 code) carries out the commands relating to each single weighing unit and allows you to make the necessary wiring to adapt to the packaging machine.

It manages up to 5 digital inputs in 24VDC (unloading consent, photocells, auxiliaries) and up to 8 static outputs 24VDC (brushes, opening command, belts command, auxiliaries).

Technical characteristics

| Static outputs power supply: | 24 VDC |

| Inputs: | 5 |

| Static outputs: | 8 |

| Item weight: | 124 gr. |

| Item size: | 122 x 79 x 34 mm |

➂ HMI display panel

The display panel represents the brain of the system, it allows you to set/view all the parameters available on the CPU and activate or not the various present funcionalities.

As regards the graphic part it is possible to connect different types of industrial HMI panels and with dimensions ranging from 4.3” to 15” according to the need; should further services or requests become necessary, we can provide you with some of our custom solutions.

➃ Remote control

It is possible to install the EasyLink product as an accessory to connect to the CPU control unit, through the RS485 serial port, which allows the system to be connected to the PC and the cloud.

This allows you to monitor and control the weighing system via desktop PC or specially developed App on smartphones and tablets, and also allows you to meet the requirements relating to Industry 4.0.

Technical characteristics

| Power supply | 12-24VDC |

| Communication interfaces: | Ethernet, RS485, CanBus |

| Item weight: | 180gr |

| Item size: | 145x90x40 mm |

WS2020

Simple and intuitive instrument for weighing management and control, suitable for dosing and packaging systems.

The user-friendly programming menu allows you to set up to 99 recipes, each of which contains all the parameters and times necessary for the operating cycle. It is also possible to program and manage the parameters both through the Ethernet interface, via Modbus TCP, and through the RS485 serial interface, via Modbus RTU; there is also the USB interface for updating the system firmware.

The tare and calibration functions allow the use of various types of load cells with different capacities, to meet all speed, accuracy and precision requirements.

Should additional functionalities become necessary, it is possible to customize them in order to satisfy every need.

Technical characteristics

| Power supply: | 24VDC |

| Weighing unit: | 1 |

| Load cell inputs: | 1 to 2 |

| Isolated digital inputs: | 4 |

| Isolated digital outputs: | 5 |

| Ethernet interface: | 1 |

| USB interface: | 1 |

| RS485 interface: | 1 |

| Item weight: | 300 gr. |

| Item size: | 145 x 100 x 70 mm |

Certifications

|  |  |

|